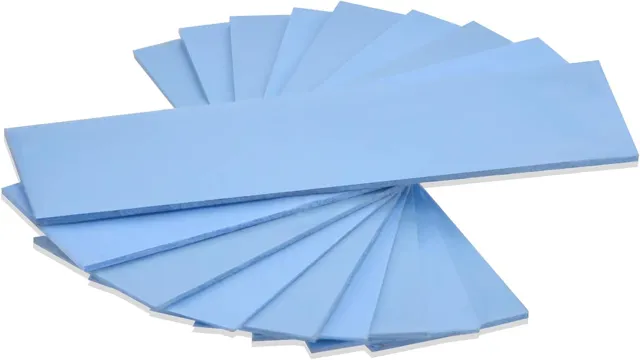

When it comes to efficiently transferring heat away from electronic components, high thermal conductivity is paramount. This is where high thermal conductive silicone pads come into play, offering an effective solution for thermal management. These pads are specifically designed to efficiently transfer heat away from critical components to prevent overheating or premature failure.

Made from high-quality silicone materials, these pads have excellent thermal conductivity, which allows them to rapidly transfer heat away from the heat source. This makes them ideal for use in a wide range of electronic applications, from LED lighting to sophisticated devices such as mobile phones, laptops, and gaming consoles. Whether you’re an engineer working on a complex electronic design or a DIY enthusiast looking to cool your computer graphics card, choosing the right high thermal conductive silicone pads can make all the difference.

With their unmatched heat transfer efficiency and ability to conform to irregular surfaces, these pads are the perfect choice for anyone who needs to keep their electronic components running cool and reliable. So, if you’re looking for an effective way to transfer heat away from your electronic components, high thermal conductive silicone pads might be the answer you’ve been looking for. With their proven performance, these pads are sure to help you prevent premature failure, extend the lifespan of your electronics, and keep them running efficiently for years to come.

What are silicone pads?

Silicone pads are an excellent thermal management solution that can be used in a wide range of applications. These pads consist of high thermal conductive silicone material and come in different shapes and sizes to fit specific requirements. They are designed to provide an efficient thermal interface between heat-generating components and heat sinks or other cooling solutions.

High thermal conductive silicone pads offer a cost-effective and flexible solution for heat management, and they can conform to uneven or curved surfaces. In addition to their high thermal conductivity, they also have excellent electrical insulation properties and are resistant to wear, tear, and impact. Whether you need a thermal interface material for your computer’s CPU or a LED lighting fixture, silicone pads can help maximize performance, increase reliability, and extend the lifespan of your devices.

Definition and Purpose

Silicone pads are non-stick, flexible silicone sheets that are widely used in the kitchen for baking. These pads are made of high-quality food grade silicone and are designed to withstand high temperatures. Silicone pads are a fantastic alternative to parchment paper and they can be used multiple times without losing their non-stick properties.

Their purpose is to provide a non-stick surface that ensures easy removal of baked goods from the pan without the need for grease or flour. Because of their flexibility, silicone pads can also be used to line baking pans of various shapes and sizes. Silicone pads make baking convenient and they also help to reduce waste since they can be reused multiple times.

Overall, silicone pads are an essential tool for any baking enthusiast who wants to achieve perfect results every time!

Types of Silicone Pads

Silicone pads are a self-adhesive and reusable product that has multiple purposes. They are usually made from medical-grade silicone and come in different shapes and sizes to fit various parts of the body. These pads are designed to adhere comfortably to the skin while providing a cushioning effect and preventing friction.

One of the main types of silicone pads is the gel pads, which are used for pressure relief on heels, toes, and other areas where the skin rubs against shoes or surfaces. Another type is the scar pads, which are used to soften and reduce the appearance of scars. They can be used on both old and new scars and are a perfect non-invasive alternative to surgery.

Silicone pads can also be used for facial treatments, such as anti-aging and hydrating masks. They are known to improve collagen production and hydrate the skin, leaving it plump and youthful-looking. Overall, silicone pads are a versatile and beneficial product that can be used for a range of purposes.

Why are thermal conductive pads important?

High thermal conductive silicone pads, commonly known as thermal pads, play a crucial role in the efficient functioning of electronic devices. When electronic devices generate heat, it can cause damage to the components, leading to permanent malfunction. Thermal pads act as a bridge between the electronic components and heatsinks, enabling heat to transfer quickly and efficiently.

These pads are made of high-quality silicone material and infused with conductive materials such as ceramic particles. The combination of materials creates a high thermal conductivity that can significantly reduce the temperature of electronic components. Using thermal conductive pads can prevent the accumulation of heat, ensuring that the devices remain functional and long-lasting.

They also act as shock absorbers, shielding the electronic components from mechanical impact and vibrations. With the continuing advances in technology and electronics, high thermal conductive pads are becoming increasingly crucial in preventing damage caused by heat.

Benefits of High Thermal Conductive Silicone Pads

Thermal conductive pads are an essential component of electronic devices as they help dissipate the generated heat. These pads are specifically designed to transfer the heat from the heat-generating device to another surface to prevent the device from getting damaged due to excessive heat. The use of high thermal conductive silicone pads has many benefits as they have a high thermal conductivity rate, which means they can transfer heat more effectively.

This prevents the device from overheating and reduces the chances of device failure. Moreover, high thermal conductive silicone pads are highly durable, which means they can last for a long time without losing their efficacy. This helps in maintaining the performance of electronic devices, leading to better functionality and increased reliability.

Therefore, the use of high thermal conductive silicone pads is crucial for the safe and efficient operation of electronic devices.

Applications and Industries

In various electronic applications, thermal conductive pads play a vital role in maintaining a consistent temperature. These pads, also called thermal pads, help to mitigate the heat generated by certain components and dissipate it, ensuring system stability. Thermal conductive pads are especially important in applications where high temperatures can cause damage, such as in LED lighting, computer motherboards, and power supplies.

In the LED lighting industry, thermal pads are necessary to ensure that the light-emitting diodes remain cool and function at optimal levels. Similarly, in the automotive industry, thermal pads are used to keep electronic components cool, ensuring maximum efficiency and performance. Overall, thermal conductive pads play a crucial role in various electronic applications, and their effectiveness can make all the difference in the performance and longevity of a system.

Performance Metrics

Thermal conductive pads are important because they play a vital role in the performance of electronic devices. These pads are designed to bridge the gap between heat-generating components and heat sinks, ensuring that heat is transferred from the device to the cooler environment. The key performance metrics affected by thermal conductive pads are temperature, power consumption, and reliability.

Electronic devices generate a lot of heat during operation, which can reduce their lifespan and performance. With the help of thermal conductive pads, heat can be dissipated efficiently, reducing the risk of damage due to overheating. Furthermore, these pads help to minimize power consumption by improving the efficiency of the device’s cooling system.

In summary, thermal conductive pads are critical components that help to regulate the temperature, power consumption, and reliability of electronic devices, ensuring that they perform optimally and have a longer lifespan.

Choosing the right silicone pad for your needs

When it comes to thermal management, the choice of the right silicone pad is crucial. High thermal conductive silicone pads are becoming increasingly popular due to their excellent heat dissipation properties. These pads ensure efficient heat transfer between electronic components and heat sinks, preventing any overheating that could lead to system failures.

To choose the right high thermal conductive silicone pad, it’s essential to consider factors such as thickness, thermal conductivity, and hardness. A pad that is too thick or soft may not provide adequate thermal management, whereas a pad that is too hard or thin may create uneven pressure and cause damage to the electronic components. Additionally, it’s crucial to select a pad with the right thermal conductivity rating suitable for the specific application’s heat dissipation needs.

By keeping these factors in mind, selecting the right high thermal conductive silicone pad for your needs can help optimize system performance and ensure long-lasting reliability.

Factors to consider

When it comes to choosing the right silicone pad for your needs, there are a few factors that you should consider. First and foremost, it’s important to take into account the type of material that you’ll be working with. Different materials may require different levels of hardness or softness in a pad to achieve the desired result.

Additionally, the size and shape of the pad should be considered, as they can impact the efficiency of your work. You’ll also want to think about the adhesive properties of the pad and whether or not it will leave any residue behind. Finally, the durability of the pad is important, especially if you’ll be using it frequently.

By taking these factors into account, you can ensure that you choose the right silicone pad for your specific needs, whether you’re using it in crafting or in an industrial setting.

Comparing different options

When it comes to choosing the right silicone pad for your needs, it can be overwhelming to navigate the variety of options available on the market. Different options exist for various purposes, from heat resistance to cushioning and more. If you need a silicone pad for food preparation, a food-grade silicone pad would be the best option as it is safe for use with edibles.

On the other hand, if you need a pad for industrial purposes, a high-temperature-resistant silicone pad would be more suitable. It is also essential to consider the thickness of the pad, especially for cushioning needs. While thicker pads offer better cushioning, they might not be ideal for specific applications that require a thinner pad.

Ultimately, it comes down to understanding the purpose of the pad and the intended usage before choosing the most appropriate option.

Conclusion

In the realm of thermal management, high thermal conductive silicone pads are the MVPs. These pads allow for efficient heat transfer between components and heat sinks, preventing overheating and prolonging the lifespan of electronic devices. Plus, they’re pretty flexible – just like our creative minds when we’re brainstorming technical solutions.

So, let’s give a round of applause to these silicone pads for keeping our technology cool and our brains hot!”

FAQs

What are high thermal conductive silicone pads, and how do they work?

High thermal conductive silicone pads are heat transfer materials used to bridge the gap between heat-generating components and heat sinks. They offer better thermal conductivity and can help dissipate heat better than traditional thermal interface materials.

What are the advantages of using high thermal conductive silicone pads over traditional thermal interface materials?

High thermal conductive silicone pads offer better thermal conductivity, reduce thermal resistance, and help dissipate heat more efficiently. They are also less messy than other thermal interface materials such as thermal grease.

Can high thermal conductive silicone pads be used in different shapes and sizes?

Yes, high thermal conductive silicone pads can be easily customized to fit different shapes and sizes of components. They can be cut into specific sizes and shapes to fit the exact dimensions of the component that needs heat dissipation.

Are there any safety precautions that need to be taken when using high thermal conductive silicone pads?

When handling high thermal conductive silicone pads, it is important to wear gloves to prevent skin irritation. It is also important to keep the pads away from moisture and avoid puncturing or tearing them while installing them onto the components.