Thermally conductive pads have become an essential component in various electronic devices. Whether you’re a seasoned tech specialist or a newcomer to the industry, understanding these seemingly simple yet incredibly important pieces is crucial. But what exactly are thermally conductive pads, and how do they work? In this blog, we’ll dive deep into everything you need to know about thermally conductive pads.

We’ll explore their composition, the importance of thermal conductivity, and the different applications they can be used for. So get ready to learn the ins and outs of one of the most critical components in electronic devices. Are you ready to discover the secrets of thermally conductive pads? Well, get comfortable because we’re about to embark on an exciting journey together.

Think of it like a road trip with a knowledgeable guide who will take you through winding roads and scenic views, all while giving you valuable insights into the world of electronics. So buckle up and get ready to learn about thermally conductive pads and their crucial role in making your devices work smoothly.

What are Thermally Conductive Pads?

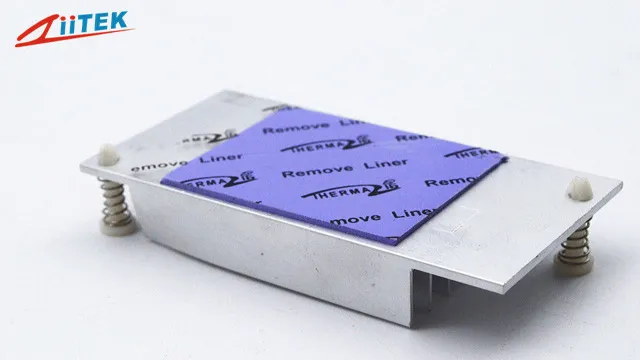

Thermally conductive pads are a type of interface material that is designed to effectively transfer heat between two surfaces. These pads are made from a solid, thermally conductive material that is coated with a thin layer of silicone or other non-conductive material. They are commonly used in electronic devices such as computer chips, LED lights, and solar panels to help dissipate heat and maintain optimal operating temperatures.

These pads are available in different sizes and thicknesses, and can be custom-cut to fit specific application requirements. Thermally conductive pads are a cost-effective solution for managing heat transfer in electronic devices, and are much easier to apply than grease or adhesive-based thermal compounds. Whether you are designing a new electronic device or upgrading an existing one, using a thermally conductive pad can help improve its performance and extend its lifespan.

Definition & Purpose

Thermally Conductive Pads, or thermal interface pads, are specialized pads used to transfer heat away from electronic components. These pads are made of highly conductive materials that are designed to remove heat from electronic devices and move it to a heat sink, where it can be effectively dissipated. The purpose of thermally conductive pads is to prevent overheating and damage to electronic components, which can lead to reduced performance and failures over time.

Overall, these pads help to ensure the longevity and reliability of electronic devices by maintaining optimal temperature levels and preventing thermal throttling.

Materials Used

Thermally conductive pads are materials used to facilitate heat transfer from one object to another. They are generally made from ceramic or silicone materials with added thermal conductive particles for better heat conduction. The advantage of using these pads is that they offer an efficient and cost-effective solution for heat dissipation.

Unlike traditional thermal pastes, thermally conductive pads are non-messy, easy to apply, and do not require curing time. They are also ideal for applications where there are uneven surfaces or sizable gaps between heat-generating components and heat sinks without compromising performance. In essence, these pads act as a bridge between two surfaces that need to transfer heat, thereby maintaining a stable operating temperature, which is critical for electronic components and devices’ longevity.

Applications

Thermally conductive pads are highly effective in dissipating heat within electronic devices, making them a vital component in many applications. One common use of these pads is in computer and server cooling systems. These pads provide a much-needed layer of insulation between electronic components and heat sinks, ensuring that heat is transferred away from critical areas in circuits.

Additionally, thermally conductive pads are used in high-powered electronic systems, such as LED lighting and power modules. In these applications, the pads play a crucial role in preventing overheating, which can lead to premature failure of the device. By using thermally conductive pads, electronics manufacturers can increase efficiency, durability, and reliability of their products.

These pads also provide a cost-effective solution compared to other methods of heat dissipation such as liquid cooling systems. Overall, thermally conductive pads are a versatile and effective solution that plays an integral role in many electronic devices.

Electronics

Electronics have become an integral part of our daily lives, and the applications for this technology are endless. From smartphones to medical equipment, electronics are used in almost every industry. In the automotive industry, electronics are used for everything from traction control systems to entertainment systems.

In the medical industry, electronics are used to monitor vital signs and to perform surgeries. In the aerospace industry, electronics are used for navigation and communication systems. The list goes on and on.

With the advent of the Internet of Things (IoT), the potential applications for electronics have expanded even further. This technology allows devices to communicate with each other and share information, creating a truly connected world. As we continue to push the boundaries of what is possible with electronics, the potential benefits to society are almost limitless.

Automotive

When you think of automotive applications, what comes to mind? Perhaps you think of cars on the road, but there are a multitude of ways in which the automotive industry is advancing technology. For starters, augmented reality (AR) is being utilized in the automotive industry to enhance the driving experience. AR can be used to display important information, such as speed and navigation, directly onto a car’s windshield.

This not only allows for safer driving, but it also creates a futuristic feel for the driver. Another innovative application is remote start technology. This allows car owners to start and heat up their car from the comfort of their home, saving time and energy.

Additionally, advanced sensors and cameras are being integrated into cars to enhance safety and improve overall driving performance. As the automotive industry continues to evolve, we can expect to see more and more applications aimed at making driving more efficient and enjoyable.

Aerospace

Aerospace applications encompass a wide range of uses that are crucial for our modern world. One of the most well-known applications is air travel, which involves the design and engineering of aircraft for commercial and military purposes. Aerospace also includes the creation of spacecraft and satellites that are essential for communications, navigation, and data collection.

The use of drones has also become more prevalent in recent years, with applications ranging from aerial photography to surveillance and even delivery services. Additionally, aerospace technology is used in various industries, such as defense, agriculture, and transportation. The development of aerospace technology has revolutionized the way we travel, communicate, and gather information, making it an essential component of our modern world.

As industries and technology continue to evolve, the aerospace sector is sure to keep up and remain an integral part of our daily lives.

Benefits of Thermally Conductive Pads

Thermally conductive pads are a crucial component in the manufacturing process of electronic devices. These pads are designed to transfer heat from the electronic component to a heat sink or chassis, preventing the device from overheating and potentially causing damage. One of the main benefits of using thermally conductive pads is their versatility, as they can be used in a variety of electronic devices such as laptops, smartphones, and even electric vehicles.

Additionally, these pads are highly durable and can last for years, ensuring the longevity and reliability of the device. Their ability to provide a consistent thermal conductivity across a wide temperature range also makes them an excellent choice for use in harsh environments, which can vary greatly in temperature. By using thermally conductive pads, manufacturers can ensure the safe and efficient operation of their electronic devices, minimizing the risk of overheating and component failure.

Improved Heat Dissipation

Improved heat dissipation is crucial in electronic devices as it can help prevent damage caused by overheating. One effective solution to this problem is the use of thermally conductive pads. These pads are made of materials with high thermal conductivity, such as silicone and ceramic, and are placed between two surfaces to transfer heat more efficiently.

The benefits of thermally conductive pads are numerous. They can help prolong the lifespan of electronic devices, improve their performance, and prevent damage caused by overheating. They are also easy to install and can be cut to fit different shapes and sizes.

Additionally, thermally conductive pads are cost-effective, making them a practical choice for manufacturers and DIY enthusiasts alike. So if you want to improve the heat dissipation in your electronic devices, consider using thermally conductive pads and enjoy the benefits they provide.

Reduced Thermal Resistance

Thermally conductive pads are a critical component in many electronic devices, providing an efficient pathway for heat dissipation. One of the key benefits of using these pads is reduced thermal resistance, which translates into more reliable and efficient performance of the device. By incorporating a thermally conductive pad between the heat-generating component and the heat sink, the pad helps to ensure that the heat is effectively transferred away from the component and dispersed into the environment.

This, in turn, reduces the risk of overheating and component failure, while increasing the longevity and reliability of the device. The result is a device that operates smoothly, with reduced downtime and maintenance, and improved overall performance. So, if you want to ensure the long-term performance of your electronic device, consider investing in a high-quality, thermally conductive pad to maximize your equipment’s thermal management.

Choosing the Right Thermally Conductive Pad

When it comes to selecting the right thermally conductive pad, there are a few factors that need to be considered. The first and most important factor is the thermal conductivity of the pad. This is because the pad needs to be able to transfer heat away from the heat source efficiently.

It’s also important to consider the thickness of the pad. If the pad is too thick, it could create an insulating barrier that prevents heat transfer. On the other hand, if the pad is too thin, it may not provide enough thermal conductivity to effectively transfer heat away.

Another consideration is the material of the pad. Silicone, acrylic, and ceramic materials are often used for thermally conductive pads. Each material has its own unique thermal conductivity properties, so it’s important to select a material that meets the specific needs of the application.

Lastly, it’s important to consider the size and shape of the pad to ensure it fits properly with the heat source and the cooling solution. By considering these factors, you can choose the right thermally conductive pad to effectively transfer heat away from the heat source and prevent overheating.

Considerations

When it comes to choosing the right thermally conductive pad for your application, there are several considerations to keep in mind. First and foremost is the materials of the pad itself. Materials like silicone or graphite can provide excellent thermal conductivity, but may not be suitable for every environment.

You’ll also want to consider the thickness and resilience of the pad, as well as any special features like adhesive backing or electrical insulation properties. Ultimately, the key is finding a pad that strikes the right balance between thermal conductivity, durability, and compatibility with your specific application. By working closely with a trusted supplier, you can find the perfect pad to meet your needs and keep your components running cool and efficiently.

Material Options

When considering thermally conductive pads, material options are an important factor to consider. There are several types of materials available, including silicone, acrylic, and ceramic-filled silicone. Each material offers different benefits, such as high thermal conductivity, durability, and flexibility.

To choose the right material, consider the specific requirements of your application, such as temperature range, electrical insulation, and mechanical stability. It’s important to note that not all materials are suitable for every application, so it’s essential to research and choose the best material for your specific needs. By selecting the right material, you can ensure efficient heat transfer and protect your electronics from damage due to excessive heat.

Conclusion

In conclusion, thermally conductive pads are like the middlemen of the heat transfer game. They bridge the gap between hot components and cooler surfaces, ensuring that the heat is distributed evenly and efficiently. Without them, electronic devices would overheat quicker than a teenager with a crush.

So, let’s raise a toast to these unsung heroes of thermal management. Here’s to the thermally conductive pads: may they always keep our gadgets cool and our laps sweat-free.”

FAQs

What are thermally conductive pads?

Thermally conductive pads are a type of material made of silicone or other polymers that are designed to facilitate the transfer of heat between a heat source and a heat sink.

How do thermally conductive pads work?

Thermally conductive pads work by providing a bridge between a heat source, such as a processor, and a heat sink, such as a cooling fan or heat pipe. The pad conducts heat from the source to the sink, helping to keep the component cool.

What are some benefits of using thermally conductive pads?

Thermally conductive pads offer several benefits, including improved thermal performance, reduced space requirements, ease of installation, and lower costs compared to other thermal management solutions.

What kind of applications are thermally conductive pads suitable for?

Thermally conductive pads are suitable for a wide range of applications, including electronic devices, power supplies, LED lighting systems, automotive electronics, and medical devices. They can be used to manage heat in any situation where heat dissipation is important.